Get Project Design 24 Hours Don't worry about the construction and management of the chicken farm, we will assist you to complete the project efficiently.

Get Project Design 24 Hours Don't worry about the construction and management of the chicken farm, we will assist you to complete the project efficiently.

Operation precautions

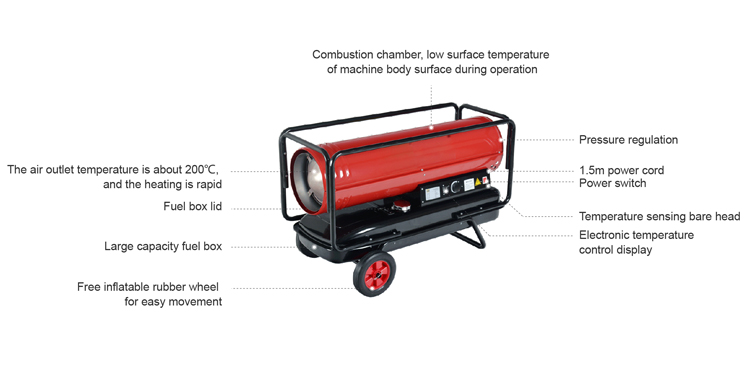

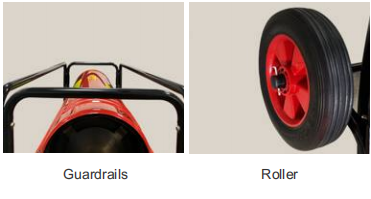

Operation precautions No black smoke, no peculiar smell >Customized nozzles--good atomization effect, 99% fuel utilization rate, perfect combustion with no black smoke and no peculiar smell. Easier operation >One-touch open--turn on the fuel box, adjust the temperature, and start heating with one button. The temperature adjustment button and the display can accurately display the predetermined temperature. The amount of remaining oil can be checked at any time through the oil gauge. >Guardrails and rollers--easy to push, prevent scald, and protect the safety of surrounding things.

No black smoke, no peculiar smell >Customized nozzles--good atomization effect, 99% fuel utilization rate, perfect combustion with no black smoke and no peculiar smell. Easier operation >One-touch open--turn on the fuel box, adjust the temperature, and start heating with one button. The temperature adjustment button and the display can accurately display the predetermined temperature. The amount of remaining oil can be checked at any time through the oil gauge. >Guardrails and rollers--easy to push, prevent scald, and protect the safety of surrounding things.

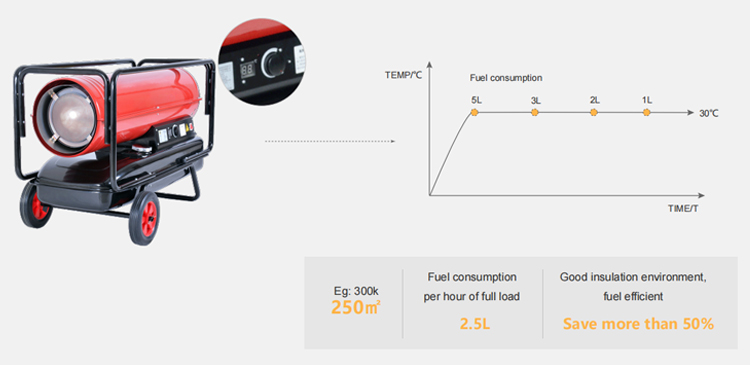

Save half of fuel >Intelligent constant temperature--According to the actual temperature of the chicken house, the hot air blower will automatically stop or start. The intelligent constant temperature saves half of the fuel in an insulated environment." >Automotive-grade circuit boards and electronic temperature controllers--more precise temperature control.5 years service life >Anti-corrosion design (air pump, circuit board, electronic temperature controller)--Multiple measures and special technologies ensure that the equipment works normally in a humid and dusty environment. >Monoblock metal fuel box--The inside of the fuel box is coated with anti-corrosion coating, which makes the inside will not be rusted, even the machine be used at intervals of one year, and extend a long service time. >Multi-layer heat exchange liner--Stainless steel thickened inner wall, corrosion resistance, high temperature resistance, the combustion chamber won't be burned through ten years. The body is insulated to ensure absolute insulation and the outer wall is not hot. >Reserve wearing parts--One filter sponge and one filter for free.

Save half of fuel >Intelligent constant temperature--According to the actual temperature of the chicken house, the hot air blower will automatically stop or start. The intelligent constant temperature saves half of the fuel in an insulated environment." >Automotive-grade circuit boards and electronic temperature controllers--more precise temperature control.5 years service life >Anti-corrosion design (air pump, circuit board, electronic temperature controller)--Multiple measures and special technologies ensure that the equipment works normally in a humid and dusty environment. >Monoblock metal fuel box--The inside of the fuel box is coated with anti-corrosion coating, which makes the inside will not be rusted, even the machine be used at intervals of one year, and extend a long service time. >Multi-layer heat exchange liner--Stainless steel thickened inner wall, corrosion resistance, high temperature resistance, the combustion chamber won't be burned through ten years. The body is insulated to ensure absolute insulation and the outer wall is not hot. >Reserve wearing parts--One filter sponge and one filter for free.  Safer fuel air heater.Four safety protection measures

Safer fuel air heater.Four safety protection measures | Protection one | Flameout protection | After power off, the fan will automatically run for 2 minutes to dissipate heat and cool down. |

| Protection two | Dumping power off protection | In case of accidental dumping during operation, it will automatically power off immediately to prevent accidents. |

| Protection three | Overheating automatic power off protection | Built-in overheating protection device, it will automatically power off when the temperature is too high, to avoid high temperature burning. |

| Protection four | Timed shutdown | Make an appointment to shutdown within 0 to 24h to avoid forgetting power off. |

| Product basic parameters | |

| Product name | DH 50 fuel air heater |

| Fuel type | Diesel/Kerosene |

| Average fuel consumption | 4.8 L/H |

| Full oil use time | 11-22 H |

| Fuel box volume | 53 L |

| Net weight | 37 KG |

| Maximum applicable area | 200-400m2 |

| Machine dimension | 1000*530*660mm |

| Packing dimension | 1030*450*540mm |

| Product working parameters | |

| Output heat | 38760 Kcal/h |

| Air volume | 1050 m3/h |

| Voltage | 220V 50HZ 1PH |

| Current | 1.2 A |

| Motor power | 250 W |

| Outlet diameter | 270 mm |

| Air pump pressure | 0.28-0.85 Bar |

| Temperature control | Built-in/External |

| Heating power | 48 KW |

Maintenance tips Every 10 days is a maintenance cycle period Inspection items 1.Clean or replace the inlet/outlet air filter sponge in the air pump. 2.Clean or replace the fuel suction filter. 3.Clean the ignition needle. (Brush off the ash carbon accumulated on the needle due to ignition.) 4.Clean the fuel box. (Open the drain nut at the bottom of the fuel box to discharge the internal residues, and clean the interior of the fuel box with clean diesel or kerosene.)"

Maintenance tips Every 10 days is a maintenance cycle period Inspection items 1.Clean or replace the inlet/outlet air filter sponge in the air pump. 2.Clean or replace the fuel suction filter. 3.Clean the ignition needle. (Brush off the ash carbon accumulated on the needle due to ignition.) 4.Clean the fuel box. (Open the drain nut at the bottom of the fuel box to discharge the internal residues, and clean the interior of the fuel box with clean diesel or kerosene.)"